The Deltak facility in the Port of New Iberia, LA spans 46 acres and offers strategic proximity to the Gulf of Mexico, just 15 miles away.

The port features a barge-capable in-slip measuring 100 ft. by 400 ft., with a water depth ranging from 20 to 25 ft. This configuration facilitates seamless maritime access, making it an ideal hub for various industrial and maritime activities.

Adding to its allure is the open-cell bulkhead, capable of efficiently handling a remarkable 6,000-ton load over an 800 ft. span. This exceptional load-out capacity ensures efficient and reliable handling of large-scale industrial projects and cargo.

Furthermore, the property’s additional 4,000 linear feet of waterfront access enhances its versatility, serving as a valuable asset for businesses in the Port of New Iberia, LA. This port location maximizes industrial and maritime operations, improving cargo handling and logistical capabilities for businesses.

Discover the potential of Deltak’s New Iberia facility. With strategic location and impressive infrastructure, seize the opportunity for success. Contact us today!

New Iberia capabilities

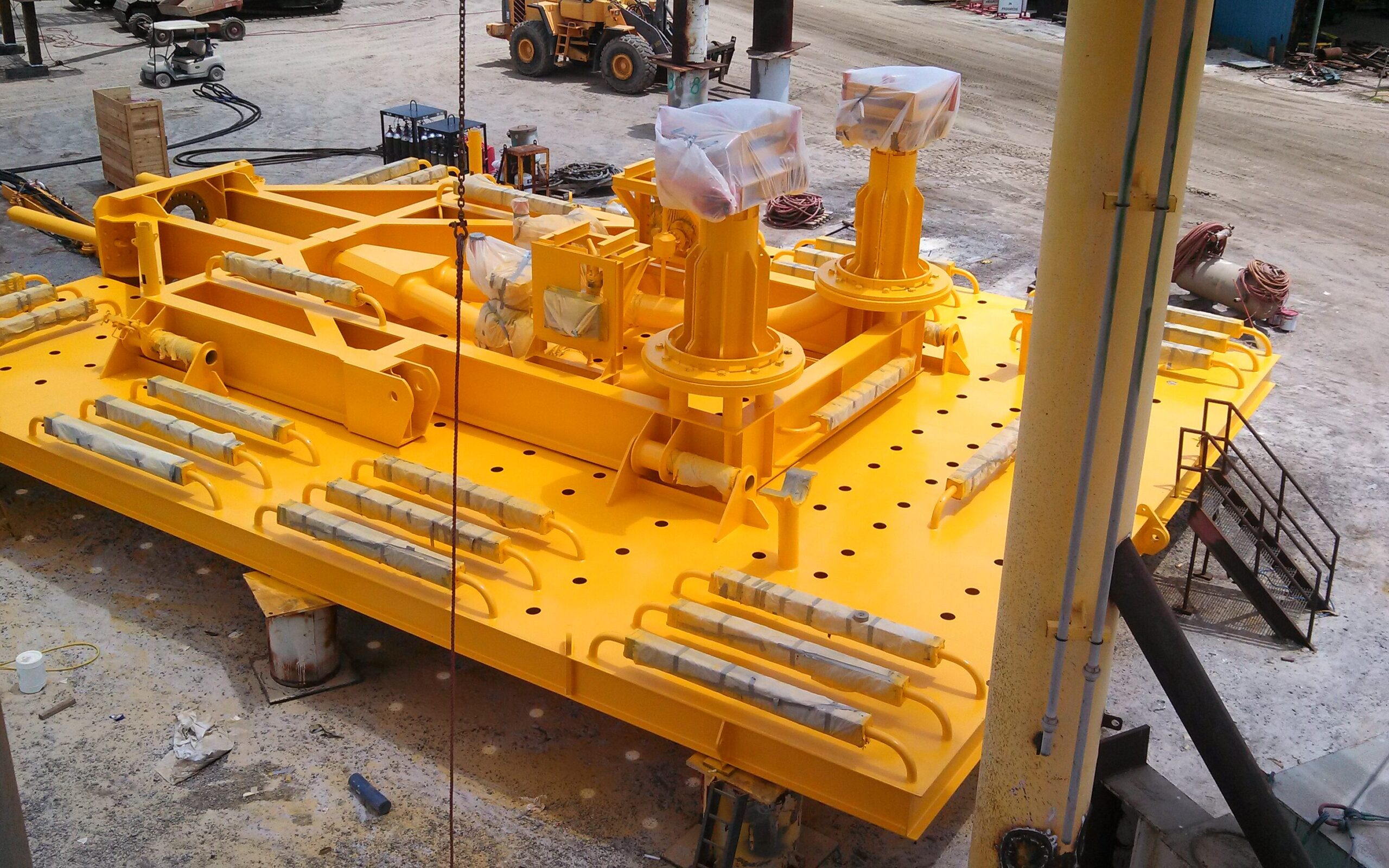

Our New Iberia facility boasts extensive capabilities, providing a comprehensive range of services within its state-of-the-art infrastructure.

- 23,000+ sq. ft. climate-controlled blasting, painting and coating shop

- 45,000 sq. ft. fabrication facility (under roof)

- 24,000 sq. ft. pipe shop

- 12,000 sq. ft. electrical and instrumentation & panel manufacturing shop

- 7,500 sq. ft. construction warehouse

- 20,000+ sq. ft. material preparation shop

- 17,500 sq. ft. structural shop